Textile Industry

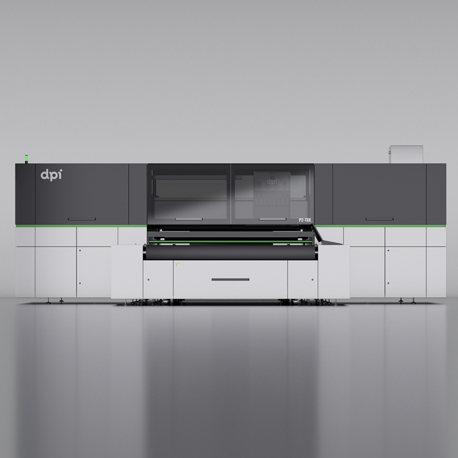

Textile Industry > Power Multi Pass Director Printer

P Series

P Series

P2-TEX

Biggest Multi Pass Direct Printer

Max 120 pcs of print heads and max daily productivity up to 50000㎡

Double beam double linear motor driven tech is designed for maximum stability and accuracy, facilitates the operation of the spray carriage and for easy maintenance of the print heads

Ultra Color Configuration and max colors up to 12. "Mirror Arrary" Printing Tech · Printing Width: 2000-3400mm

Productivity: Single/Double Roll Print Mode, Super Flexible, Extremely Productive

Customiazation: Variable Print Head Configurations, Optimize Initial Investment Costs

Highly Productivity and Maximum Compatibility for Different Pattern Designs

Ink Circulating System: Individual negative pressure control system effectively ensures ink circulation

Effectively Guarantee the stability and quality of printing work

lndividual print head moisturizing applied for reactive ,acid,disperse and pigment ink

Belt washing system with double individual sink design, pantented design of belt cleaning system to ensure that the guide belt does not stick to ink, fibres and impurities while printing at high speeds

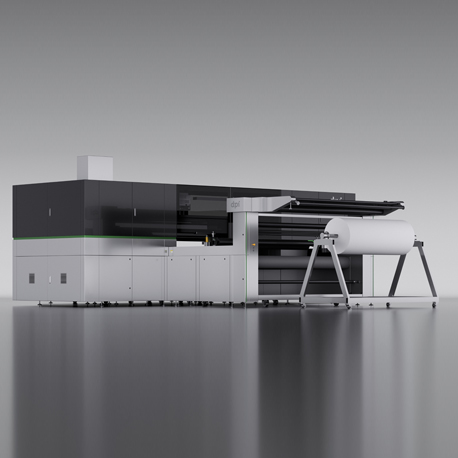

Textile Industry > High-Speed sublimation Printer

B Series

B Series

B2-TEX

Ultra-High Productivity up to 1100 SQM Per Hour.

Patented oriented structure design, anti-wrinkling.

Optimized design of the active roller and rubber roller, no slip during batch production.

Independent controlled negative pressure system, high compatibility and stability of ink supply.

Integrated heating device, saving space, intelligent drying, synchronous printing speed; improve printing efficiency and save energy.

Winder and unwinder intelligently controlled by Servo + PLC system, automatic adjustment, compatible to Jumbo roll.

Automatic moisturizing and flushing kit for print head.

Optional print head for Breeze Serial (Epson and Kyocera).

Automatic optimization of magnetic shan error can eliminate vertical lines and other effect problems.

Independent waveform during flash spray. Improve the cleaning effect.

customizing color bar and image footnote.

Automatic matching of different print precision mode.

Quickly upgrading and copying of processing.

| Model | TBE30-1900 | ||

|---|---|---|---|

| Print Head | Epson I3200-A1 | ||

| Max Resolution | 600*1800dpi | ||

| Drops | 3.8~9.4 | ||

| Qty of Print Head | 24~30 | ||

| Max Print Width(mm) | 1900 | ||

| Colors | 4 | ||

| Height of Platfom(mm) | 1030 | ||

| Media | Sublimation transfer paper | ||

| Ink | Sublimation ink | ||

| Air | 0.6Mpa|1m³/hr | ||

| Power Supply | 380VAC±10%, 50-60Hz | ||

| Power | 8KW (Printer)+14KW (Dryer) | ||

| Dimension(mm) | 2550*4050*1850 | ||

| Weight(kg) | 2000 | ||

| Standard Configuration | Dryer + Winder/Unwinder | ||

| Print Speed | 1pass | 1pass | 2pass |

| 240*1800dpi | 300*1800dpi | 240*1800dpi | |

| 1100㎡/hr | 980m2/hr | 550㎡/hr | |

| Model | TBK12-1900 | ||

|---|---|---|---|

| Print Head | Kyocera KJ4B-QA06 | ||

| Max Resolution | 600*1200dpi | ||

| Drops | 5~12 | ||

| Qty of Print Head | 8~12 | ||

| Max Print Width(mm) | 1900 | ||

| Colors | 4 | ||

| Height of Platfom(mm) | 1030 | ||

| Media | Sublimation transfer paper | ||

| Ink | Sublimation ink | ||

| Air | 0.6Mpa|1m³/hr | ||

| Power Supply | 380VAC±10%, 50-60Hz | ||

| Power | 8KW(Printer)+14KW(Dryer) | ||

| Dimension(mm) | 2550*4050*1850 | ||

| Weight(kg) | 2000 | ||

| Standard Configuration | Dryer + Winder/Unwinder | ||

| Print Speed | 1pass | 1pass | 2pass |

| 300*1200dpi | 508*1200dpi | 508*1200dpi | |

| 1030㎡/hr | 860㎡/hr | 430㎡/hr | |

Textile Industry > High-Speed Direct Printer

G Series

Humanized design, durability and easy operation.

Max. 48pcs print head, Max. colors up to 12

Printing width: 2000mm-3200mm

The unique ink system is compatible with: Reactive, Acid, High Energy Disperse, Pigment and other ink applications.

Applicable to various textile fabrics.

Independently developed on the printing software and motion control system developed by DPI independently, it can realize high resolution and easy operation.

High-precision mechanical design and sophisticated motion control system optimize the printing performance.

High-precision transportation belt and transmission parts.

Flexible queues management for continuous printing, unattended production.

The high-precision industrial mechanical design and sophisticated motion control system makes a high quality printing performance.

2000mm of printing width compatible to various fabrics of weave/knitting.

Multi-purpose cloth feeding structure, equipped with expansion centering and constant tension device,applicable to all kinds of textile fabrics.

Advanced belt washing system design, dual sink design, Independent water supply and drainage.

The overall cleaning structure is equipped with double brush rollers, sponge rollers, air knives, water-absorbing cloth rollers and a belt drying system, which effectively ensures that the guide belt is clean and does not leave water stains, and improves the stickiness of the guide belt.

Parameter

| Model | G2-48 | G2-48 XL | ||||

|---|---|---|---|---|---|---|

| Printing Resolution | 600~2400 | G2-48 XL | ||||

| Ink Drops | 5、7、12、18 | 5、7、12、18 | ||||

| Number of Printhead | 32~48 | 32~48 | ||||

| Max. Print Width | 2000 | 2000 | ||||

| Number of Color Channel | 6~12 | 6~12 | ||||

| Height of Printing Platform | 980 | 980 | ||||

| Fabrics | Pure nature fiber (such as Cotton, Silk, Linen, Wool), Polyester, Nylon and other Optical fiber etc. | Pure nature fiber (such as Cotton, Silk, Linen, Wool), Polyester, Nylon and other Optical fiber etc. | ||||

| Inks | Reactive, Acid, Disperse,Pigment etc | Reactive, Acid, Disperse,Pigment etc | ||||

| Air Compression | 0.6 | 0.6 | ||||

| Power Supply | Three phase 5lines | Three phase 5lines | ||||

| Power | 22 | 22 | ||||

| Dimension (L*W*H) | 5700x5000x2300 | 6900x5600x2300 | ||||

| Weight | 6 | 8 | ||||

Production Speed (Caculate As 1800mm Printing Width)

| Model | Printing Resolution | No.Printing Pass | Single Direction Capacity (m/hour) | Double Direction Capacity (m/hour) | |||||

|---|---|---|---|---|---|---|---|---|---|

| G2-32 | 508*600 | 1 | 353 | 570 | |||||

| 508*1200 | 2 | 200 | 324 | ||||||

| 508*1800 | 3 | 134 | 216 | ||||||

| 508*2400 | 4 | 100 | 162 | ||||||

| 600*600 | 1 | 315 | 508 | ||||||

| 600*1200 | 2 | 175 | 283 | ||||||

| 600*1800 | 3 | 116 | 188 | ||||||

| 600*2400 | 4 | 87 | 141 |

| Model | Printing Resolution | No.Printing Pass | Single Direction Capacity (m/hour) | Double Direction Capacity (m/hour) | |||||

|---|---|---|---|---|---|---|---|---|---|

| G2-48 | 508*600 | 1 | 328 | 530 | |||||

| 508*1200 | 2 | 186 | 300 | ||||||

| 508*1800 | 3 | 124 | 200 | ||||||

| 508*2400 | 4 | 90 | 145 | ||||||

| 600*600 | 1 | 292 | 472 | ||||||

| 600*1200 | 2 | 163 | 263 | ||||||

| 600*1800 | 3 | 108 | 174 | ||||||

| 600*2400 | 4 | 81 | 131 |